*this post originally appeared on COMUTIQ’s blog: https://www.comutiq.com/blog

One of the key factors contributing to growth in the electric vehicle (EV) market has been the substantial decline in battery costs. While much attention has been given to the price reductions of raw materials like lithium, nickel, and graphite, there are other crucial elements that have played a pivotal role in driving down overall battery costs. Read on for more insights.

Main Cost Items in Lithium-Ion Battery Production

Before diving into the cost reductions, it’s essential to understand the primary components contributing to the cost of a lithium-ion battery:

-

- Raw Materials: These include lithium, nickel, cobalt, and graphite, which form the core of the battery’s electrochemical processes.

-

- Manufacturing Costs: This encompasses labor, energy consumption, and the production capacity impacting machinery and equipment used.

-

- Research and Development (R&D): The ongoing development of new battery technologies and materials to improve performance and reduce costs, plus the levels of overall investment.

Raw Material Price Reductions

The past few years have witnessed a notable decline in the prices of key battery materials.

The price of lithium has dropped 50% in the last year, due in a large part to decreased demand on a slowdown in the global economy. The price of nickel has also dropped, but not as significantly, with Indonesia now dominating primary supply. The price of graphite has remained relatively stable despite the world’s largest producer China, introducing export controls on some products.

However, it’s important to note that while raw material costs have contributed to overall cost reductions, they are not the sole driving force.

Logistics

The cost of shipping (inbound and outbound) around the World has increased in recent years. Most significantly has been as a result of geopolitical and environmental problems especially in the last year – significant traffic has been re-routed from the Red Sea around southern Africa, while drought in the Panama Canal led to reduced traffic and weight limits, together increasing transit costs and times, even though these have fallen back partially in the last 3 months.

Labor

The cost of labor is a variable factor in the production of lithium-ion batteries and depends on the location of the manufacturing facility, with North American and Western European manufacturers having difficulty to control this cost. Consequently, there has been a trend of manufacturers moving their production facilities to or entering into partnership agreements with, countries with lower labor costs

Energy

The cost of energy varies by region and the type of energy used. In recent years, there has been a trend of manufacturers using renewable energy sources to power their production facilities, but traditional sources still dominate. Compliance regimes for local environmental regulations differ between countries, giving some short-to-medium term cost advantages.

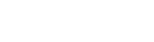

Scale Benefits and Technology Improvements

We must also delve into the realm of manufacturing process improvements and technological advancements to further broaden our understanding of how things have been changing:

-

- Manufacturing Process Improvements:

-

- Speed and Efficiency: Significant strides have been made in optimizing electrode manufacturing processes, leading to a tenfold increase in speed.

-

- Reduced Finishing Time: Processes like forming and aging have become more efficient, resulting in a reduction of around 40% in time and cost.

-

- Improved Assembly and Scrap Rates: Advancements in assembly techniques and quality control have led to a 35% reduction in assembly time and a decrease in scrap rates.

-

- Manufacturing Process Improvements:

-

- Technology Improvements:

-

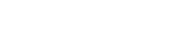

- Battery Chemistry: Research and development efforts have focused on exploring alternative battery chemistries, with a move towards lithium-iron-phosphate (LFP) from NMC, to give cost and performance advantages.

-

- Cell Design: Innovations in cell design, including the development of pouch cells and bigger cylindrical cells, have impacted manufacturing costs and performance. Introducing structural battery cells has also reduced overall battery pack costs.

-

- Technology Improvements:

-

- Scale Improvements

-

- The increasing demand for electric vehicles has led to economies of scale in battery production. As manufacturers ramp up production, leaders (e.g. CATL, BYD) can benefit from lower unit costs due to factors like bulk purchasing of raw materials, improved production efficiencies, and optimized supply chains.

-

- Scale Improvements

Regional Discrepancies in Costs

It’s important to acknowledge that battery costs vary significantly across different regions. Factors such as labor costs, energy prices, and government policies can influence the overall cost of production and we see that China, and to a lesser extent South Korea and Japan, have clear competitive advantages compared to North America and Europe.

Outlook for 2025 and Beyond

Looking ahead, and apart from raw material costs which are likely close to bottoming, the trend of declining battery costs is still expected to continue. As manufacturers continue to invest in research and development, refine manufacturing processes, and benefit from economies of scale, we can anticipate further reductions.

Conclusion

While the price reductions of raw materials have played a significant role in the decline of battery costs in recent years, it’s essential to recognize the broader factors at play. Manufacturing process improvements, technological advancements, and economies of scale have all contributed to making lithium-ion batteries more affordable. As the EV market continues to grow, we can expect further innovations and cost reductions, paving the way for a more electrified and sustainable transportation landscape.

We calculate a Battery Cost Index that tracks raw material, labor, and energy costs across key regions and countries – and it has dropped 25% in the last year, and almost 60% since the start of 2023. This helps to highlight key changes and trends in the various cost factors and is therefore a powerful tool that enables companies to benchmark cost trends, optimize their supply chains, and stay competitive. We also produce other indices including a full vehicle index. Whether you’re in the automotive industry or any other sector, our indices can be applied to your products to provide valuable cost reference benchmarks.

Ready to optimize your operations? Contact us today to schedule a meeting and explore how we can help.